The Cable Connection – Part 3

Interconnecting equipment & wiring

by Jim Tanenbaum, CAS

Interconnecting your battery-powered equipment with other department’s (or your own) AC-powered units is another major trouble spot. Hard-line feeds to video assist are the main offenders. Their AC power often leaks back and produces a hum or buzz in your audio. A supply of 1:1 line-level audio isolation transformers should be in your kit. They are also useful when tapping into the output of an existing house P.A. system. (Sescom offers units with plastic housings, so the previously-mentioned problem of grounded connector shells is nonexistent.)

A video hard-line feed to your cart can also cause a problem, but video isolation transformers are available to correct it (though they cost considerably more). IMPORTANT: Do not confuse video isolation transformers with video hum-bucking transformers designed to eliminate disturbances in the video image caused by AC power leakage, as many of them do not provide isolation of the output signal from the input.

In general, isolation transformers should be inserted as close to your cart as possible, both to reduce the capacitive loading of the secondary and to minimize pickup of additional interference with the cables on your side of the transformer. Additionally, this practice reduces the chance of other departments accidentally collecting your transformers along with their gear during wrap.

You may require mike-level splitter/isolation transformers if you need to get a separate feed from a particular mike before it goes into the house mixer board (or if their system is too low quality). Remember that a splitter transformer will drop each output -3 dB from the input, so the house mix panel gain will have to be adjusted accordingly.

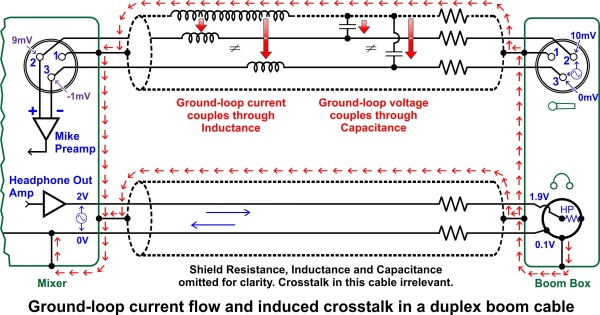

An audio ground loop problem area concerns the “duplex” cables run between the cart and the boom operator. The cable contains two circuits: a feed from the boom mike and an audio return to the operator’s headphones. A typical duplex cable has two individually-shielded 2-conductor cables inside. The shields are covered with a plastic jacket so they are insulated from each other. Duplex cables are often terminated in 5-pin XLRs, or in some cases, the boom operator’s end is permanently attached at the connector box. This box has a 3-pin female XLR to receive the fishpole plug, and a quarter-inch phone jack for the headphones. If the duplex cable is not attached directly to the box, there will be an additional female 5-pin XLR for the cable and a male panel connector on the box. The most common wiring scheme is:

Pin 1 = Both Shields

Pin 2 = + Mike

Pin 3 = – Mike

Pin 4 = + Phones

Pin 5 = – Phones

Shell = Connected to Pin 1

For starters, the line-level headphone return is about 60 dB (1,000x) above the mike signal. Next, headphones are unbalanced, using a TS plug. Finally, the metal connector box has the metal collar (sleeve contact) of the phone jack mounted directly to it, and also the shells of the XLR-3 (and the XLR-5 if used) connected to it. Usually, this scheme works okay because the boom operator is being fed the same audio coming from the mike, so any ground-loop-induced crosstalk is inaudible. Or at worst, it adds a small amount of additional high-frequency boost from capacitive coupling, which can easily be dealt with a little HF roll-off on the mix panel.

I wasn’t aware of any of this when I first encountered the problem. It was on a show where I had two boom operators, each receiving a common mix headphone return. When I PFLed (soloed) each boom mike, I could hear a faint crosstalk from the other mike. I immediately knew it was capacitive coupling, because the low frequencies were missing, but wrongly assumed it was occurring within my mix panel. I quickly unplugged one of the duplex cables and the crosstalk disappeared, so my suspicions were confirmed (wrongly). Murphy was insidiously at work here—the duplex cables were easy to reach; the 3-pin XLRs at the rear of the mixer were not. Fortunately, the next thing I did was to pull the mixer all the way out and move the 2nd boom from Channel 5 to Channel 1, leaving the 1st boom in Channel 6. To my surprise, this didn’t affect the crosstalk. Then I unplugged the mike from Channel 1 and left it unconnected—when I listened to Channel 6 again the crosstalk was still there, unchanged. Aha! The crosstalk is in the duplex! As a check, I plugged the 2nd boom back into Channel 5 and unplugged the 1st boom. The crosstalk was in that duplex too (see the circuit diagram below).

Here’s what happened: the IR drop in the two wires of the headphone circuit, which has much more current as well as much more voltage, was raising the far end of the headphone feed above ground. Since the headphone jack effectively connected one side of the circuit (the sleeve) to the metal housing of the connector box, the excess voltage drove a ground loop current back down both shields to mix panel on the sound cart, where the headphone was also grounded to its chassis. This was the signal that was capacitively (and slightly inductively) coupling from the shield to the inner conductors of the mike cable. The mike circuit was balanced, but balanced circuits are never perfect. The solution was simple—I replaced the headphone jack with one that had a plastic mounting collar and “floated” (insulated from the metal housing) the headphone ground. No more crosstalk. (Naturally, the plastic jacks are not as durable and reliable as the metal ones.

If you have the room, however, you can enlarge the jack mounting hole from 3/8- inch to 1/2-inch diameter with a stepped single-flute drill bit, and insulate the metal jack collar with two 3/8” x 1/2” plastic shoulder washers, one on each side of the mounting surface.) If you send a stereo feed to the boom headsets, using the two inner conductors for the left and right channels and their shield for the common, insulating the jack will only work if the cable is wired directly into the box, so the headphone circuit shield can be kept isolated from the mike shield. If there is a 5-pin XLR at the box, and both shields are connected to Pin 1, insulating the jack won’t make any difference, because the headphone circuit shield and the mike circuit shield are connected together at the connector. You can, however, float that end of the mike circuit shield, which will help somewhat, because now the headphone shield will have to capacitively couple to the mike shield first, reducing the amount of voltage on the mike shield. Also, there will be no headphone return current flowing down the mike shield, so there will be no IR drop, and thus, even less voltage. (Of course, since now the headphone current is only flowing down one shield instead of two, its IR drop will be twice as much, but the crosstalk to the mike circuit will still be less.)

For me, this is now all academic, because I use radio links coming and going, and there is no longer any possibly of ground loop crosstalk. Or so I thought.

Recently, I had another crosstalk problem. Because the various pieces of equipment on my cart are still connected with cables, I wasn’t home free. Eventually I found the problem, using the techniques described below. I’d made some mistakes early on when building my cart, and never thought to go back and look for potential trouble spots after I learned more.

SOUND CART CONSTRUCTION TECHNIQUES TO MINIMIZE PROBLEMS

1. (Assuming your sound cart has a metal frame.) Make sure that all portions of the structure of your cart are firmly bonded together. Welding or brazing is best, but securely tightened bolts and nuts will do—be sure to use lockwashers under the nuts. (Or elastic-insert nuts that are inherently vibrationresistant.) Periodically inspect fasteners for looseness and retighten. If your cart has portions that fold on a hinge or pivot, especially if there are non-metallic anti-friction washers in the rotating joint, bypass it with a short flexible wire jumper, as described in Item 6 below. If you are using a plastic rack mount case, make sure all rack mount strips are solidly bonded with heavy wire jumpers to any separate connector strips or other metal panels containing circuit components or devices. This is especially true for RF or video circuits.

2. If equipment added over the years has resulted in a rat’s-nest of cables, it’s time to disconnect everything and rewire neatly. Keep power cables away from audio ones, and timecode or other digital signal cables away from analog signal ones. Keep video and RF coax cables away from everything else. Interconnecting cables should not be any longer than necessary, but take into consideration that you might have to pull a unit out for troubleshooting or maintenance while it is still connected.

3. Unfortunately, there is no standard among the various equipment manufacturers regarding the wiring of their audio input and output connectors. Some of them tie Pin 1 to the chassis/ case of their equipment, and some do not. You can check each connector with an ohmmeter—a reading of 0-1 Ù indicates a solid connection and a reading over 10 MÙ indicates no connection. Also unfortunately, you will often get a reading of 10-100 KÙ or higher, or a reading that initially is near zero, but quickly kicks upscale to some high value. These two conditions obtain when there are electronic components connected between the circuit ground and the device’s chassis, usually for RF interference suppression. When you first set up your cart, you can treat this situation as a floating ground. 4. If you have a patchbay for mike-level signals, be sure that the backside is shielded by being completely enclosed in a metal housing. 5. “Empty” braided shielding is available from professional electronics parts distributors. It comes as a flattened-out tube, and in this form, is often used for high-current jumper or ground straps. You can open it up and run cables that need to be shielded through the central opening, to keep interference either in or out as the case may be. The hollow cylinder of shielding increases to its maximum diameter when the ends are pushed together, and decreases to its minimum when they are pulled apart. Maximum flexibility occurs somewhere between these two extremes. I shield all my powering cables this way, with the shield grounded to the equipment case and floating at the battery or power supply end. (To be honest, for low-current devices I simply use shielded heavy-duty 20-gauge mike cable instead.)

6. If you don’t have rack-mounted equipment, with the front panels securely bolted in place, ground all your equipment enclosures to the frame of your sound cart. (Or to each other if you don’t have a metal cart.) You can use one of the device’s enclosure screws to make the connection. Use the shortest possible length of 12-gauge or 14-gauge stranded cable with terminal lugs crimped on each end. I use a “ring” terminal for security on the cart end, and a “hook” terminal at the equipment end so the screw just needs to be loosened rather than removed completely (with the possibility of being dropped and lost) to disconnect the cable. Then insulate all of the enclosures where they might touch the metal frame of your cart (see Item 8 below).

7. Additional shielding is occasionally required. Aluminum foil tape (used for sealing metal air ducts) is readily available from heating and air-conditioning equipment dealers in 2-inch or 3-inch widths. This can be used to seal joints in equipment cases where interfering signals are entering or escaping. It can also be wrapped around a bundle of cables that are permanently installed in your cart. The only problem is in securing a good ground connection to the foil. Several inches of tape at the end of the wrap can be folded over to make a tab which is then screwed to the grounding point. Unfortunately, aluminum oxidizes and becomes an insulator, so the screws will have to be periodically loosened and retightened. Using copper foil adhesive-backed tape solves this problem, because copper oxide is not an insulator. Also, ground wires can be soldered directly to the tape. The only drawback is that the copper tape is difficult to find, and may have to be bought online.

8. An often-overlooked source of static comes from rubbing metal contacts near sources of RF energy such as Comtek or radio mike transmitters. An equipment chassis or even an isolated piece of metal, especially if it has a dimension close to a quarter-wavelength of the RF, will pick up some of the radiated energy. Now, if this piece rubs against another piece of metal (whether grounded or not), there will be tiny (invisible) sparks between them that will re-radiate the single-frequency energy as wideband static, and this can infiltrate the wiring on your cart. Rubber or plastic mats on the metal shelves of your cart will help to prevent this, but two metal objects on the mat that touch each other can still cause trouble. I first experienced this with two large screwdrivers sitting on a wooden workbench next to a radio mike transmitter I was testing. They produced static in the audio whenever their shafts touched. The RF noise they radiated was picked up by the transmitter’s audio circuits. NOTE: Some car seats have internal metal springs that rub, and cause static in radio mikes worn on the actors’ back. Relocating the transmitters to the front of the actors’ body usually eliminates the problem as well as increasing the radiated RF power.

9. One other insidious RF problem occurs because of the “skin effect” in which RF energy rides along the outside of cable shielding without penetrating into the inner conductors. Whatever is feeding the transmitter may be affected by this. The audio input to a Comtek transmitter is a good example. The factory-supplied input cable incorporates a ferrite RF choke (which acts like an inductance) at the transmitter end, but you can buy ferrite hollow cylinder chokes from electronic parts dealers for making up your own cables. With an existing cable, you can either remove the connector at one end to slip on the choke and then reattach it, or buy a “split” choke where the ferrite cylinder comes as two halves in a plastic housing that snaps around the cable.

10. The RF bypass capacitor and resistor combination mentioned earlier can also be used on specific cables to deal with pickup from transmitters located on the cart.

11. Secure all the loose cables with nylon cable ties. For ease of servicing, you can purchase reusable ties with manual release tabs.

The next issue will provide specific troubleshooting advice for crosstalk and also address safety considerations. This will conclude the series.

Text and pictures ©2012 by James Tanenbaum. All rights reserved.