The Cable Connection: Part 4

CHECKING YOUR RECORDING CHANNEL FOR CROSSTALK PROBLEMS

by Jim Tanenbaum CAS

When you have finished configuring your sound cart, begin checking for problems. You will have to repeat the tests several times, monitoring from your recorder, backup recorder (if used), and mix panel. When you have finished with this first round of testing, check all your sends: Comtek, feed to video assist, etc., for crosstalk in them.

You will need a battery-operated tone generator, with 100 Hz, 1 KHz, and 10 KHz sine wave frequencies, both mike and line-level outputs, and adapter cables to allow you to connect to whatever type of audio input connectors (XLR, TA, etc.) your equipment uses. “Dummy” loads to terminate open cables or inputs are also helpful in tracking down the more refractory cases, but you may not need them. I made male and female XLR connectors with metal-film resistors (low internal noise) soldered between Pins 2 and 3: dynamic mike = 150 Ω, condenser mike = 2 KΩ in series with a 100 mfd NP tantalum capacitor, line = 600 Ω, and hi-Z = 20 KΩ. All the shells are connected to Pin 1.

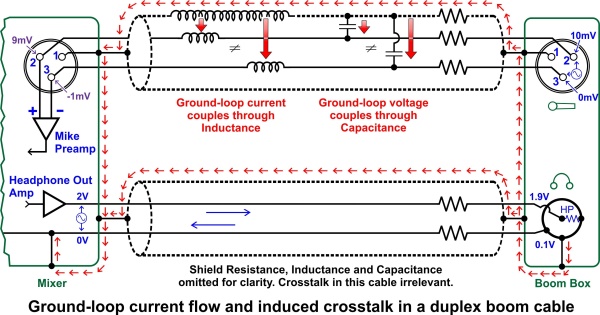

Without getting too deeply into electronic theory, capacitive crosstalk is characterized by an increased proportion of higher frequencies— it sounds tinny, like a really old-fashioned telephone. This type of crosstalk increases as the distance between the two wires decreases. Furthermore, it requires only a source voltage, not current (e.g., the headphone feed in a duplex cable when the boom op’s phones are not plugged in). The type of insulating material separating the two wires doesn’t make too much of a difference.

Inductive crosstalk is the inverse of capacitive in that low frequencies couple more easily than high ones, but here the surrounding material makes a difference: ferrous material couples a magnetic field much more effectively than air for low frequencies. However, you will not encounter this situation often because there is seldom any iron or steel involved. Inductive crosstalk requires current to be flowing in the source circuit, so in the example above, if the crosstalk increases when the boom op’s phones are plugged in, you now have a contribution from inductive coupling. (Or not—the current drawn by the headphones will increase the IR drop, so there will be less voltage to capacitively couple.) In addition to an increased level, you may notice a greater proportion of lower mid-range frequencies.

(Or not—it depends on how tightly the two wires are twisted, and how evenly.)

Follow the procedure below to check your gear for crosstalk or interference pickup:

1. To begin, be sure all equipment is switched off.

2. Disconnect all cables from the mixer’s channel inputs. Turn on the mixer and push all the faders to full open. Turn the headphone volume all the way down, in case there is a routing problem and the full-level tone goes directly to them. Plug your headsets into the mixer’s jack and slowly turn the volume all the way up. You should not hear anything except a faint hiss. Turn down the volume (to avoid any transient pops) and switch on all the other cart-mounted equipment, one unit at a time. Raise the headset volume to listen as each new unit is powered up. If the hiss or any other sound is noticeably louder, investigate the reason.

3. Make sure the headphone volume is down. Set the tone generator to 1 KHz at mike level, and plug it in to the mixer’s Channel 1. Adjust the channel fader and trimmer to give a 0 dB (full scale) reading on the mixer’s meter. Solo all the other channels and listen for crosstalk, turning the headphone volume up to listen and then down again for each channel. You will hear a certain amount of crosstalk, perhaps -55 dB to -70 dB down. It should be the same on all the other channels, or slightly louder on the adjacent Channel 2. Repeat this procedure with the generator set to 10 KHz. The crosstalk level may be somewhat higher. Then repeat with the generator at 100 Hz. The crosstalk should be noticeably lower. Now move the tone generator to Channel 2. Listen for crosstalk on all the other channels. Continue to move the tone generator through all the remaining channels. Finally, pull all the faders down and listen for any tone bleed-through. This sequence of tests establishes the baseline crosstalk level for all the following tests.

4. Repeat these mixer crosstalk tests with line-level inputs. Be sure to use the separate line input connectors if provided, instead of simply padding down the mike inputs. You may notice slightly more crosstalk because of the increased voltage entering the mixer’s internal wiring, especially the faders-closed test. This is normal, if the increase is not excessive.

5. NOTE: The above tests are extra-sensitive because the inputs are open-circuited. When a mike or other device is connected, the residual noise floor will be lower. You could check this by connecting the appropriate dummy load, but at this stage it is probably not necessary.

6. Connect the radio mike receiver outputs to the mixer inputs. As a general practice, use the receiver’s line-level outputs and the mixer’s line inputs. Depending on the type of radio mikes you have, they may produce more hiss or other noises when the transmitters are off. Turn on the transmitters (without a mike plugged in) to ensure that all the receivers mute/squelch properly. After you have checked for noise in every receiver, move the transmitters around your cart to see if their RF gets in anywhere. When finished with this test, switch off all the transmitters and disconnect the receivers.

7. Make sure your mixer is connected to the recorder in whatever arrangement you use (e.g., mix to Ch 1, ISOs to Ch 2, Ch 3, Ch 4…). Turn the recorder’s headphone volume all the way down, then move your headphones to the recorder. Use the mixer to send a 0 dB tone to the recorder’s Channel 1, and then listen to all the other recorder channels for crosstalk. Turn the headphone volume up slowly each time. Next, connect the tone generator to the mixer input that will send a tone to the recorder’s Channel 2 and listen for crosstalk on the other recorder channels. Finally, check all the other recorder channels in the same manner.

8. If you use a backup recorder, perform the same tests on it.

9. Check all the external feeds, starting with the Comtek (or whatever wireless monitors you use). Use closed-cup headphones to reduce bleed-in of outside sounds. Be sure the Comtek receiver’s volume control is all the way off. Start with all the faders down on the mixer. IMPORTANT: You will need to calibrate the Comtek receiver’s output level to match the mixer’s. Temporarily reduce the tone generator’s output to -30 dB, and open the corresponding channel fader to give -30 dB on the meter. Slowly raise the mixer’s headphone volume to maximum, raising or lowering the tone generator’s output level to give you a comfortable SPL (Sound Pressure Level) in the headphones when the volume is full up. Now alternate plugging in your phones from the mixer to the Comtek receiver, adjusting the receiver’s volume control until the tone levels match. At this point, the control should be near maximum. If you can’t get the tone as loud with the control all the way up, you will have to make a mental note of how much lower it sounds, and judge the test results accordingly. If you reach the same loudness with the control well below maximum, especially if it is below the point where it is usually set, there may be a problem with the level of the signal going in to the Comtek transmitter—check it. It is also possible that the sensitivity and/or impedance of your headphone is markedly different from the lightweight phones you use with the Comtek—compare them.

10. If you have found no crosstalk or interference problems, give thanks to Murphy and take a break. But if you do have trouble, keep your headphones on and check the following:

11. Is the trouble in only one device? (e.g., in the recorder’s headphone monitor but not the mixer’s?) Unplug the audio, video, and timecode cables from it one at a time. If the problem persists, power it from another source. (e.g., if you have a common 12-volt supply on your cart, unplug the equipment and run it from a separate battery.)

12. Can you tell from the sound what kind of crosstalk or interference you have? (e.g., if the problem is TC bleed from recording TC on one audio channel of the recorder, have you used an external pad to drop it 20 dB or 30 dB?) If you can identify the culprit, start with that piece of equipment.

13. If you have an AC hum/buzz problem and are not running anything from AC, make sure it’s not sneaking in somehow. Are you using an AC-powered worklight whose metal parts are touching your cart? Have you left a cart battery charger connected? Have a plugged-in electric drill on a lower shelf? If you unplugged a feed from video assist, is the metal shell of the plug still touching something metal on your cart?

14. If you are running on AC, is everything plugged in to the same outlet? A surge-protected outlet strip is a good start. Is there continuity for the third (grounding) pin all the way to the power source, including any extension cords? Is the third pin receptacle in the wall outlet properly grounded? (Using an AC voltmeter, measure the voltage from it to a known ground. Cold-water pipes are good, unless plastic water pipes are involved.)

15. If nothing specific is indicated, perform a general check.

16. Are all interconnecting cables firmly seated? If they are twistlock types, are they secure?

17. Wiggle each end of each cable at the juncture with the plug to see if that affects the problem. Cables usually fail at the strain relief, and the shield often fails first.

18. Loosen the cable clamps and separate all the cables in the bundle.

19. Isolate the power source of each piece of equipment in turn. Run it from a separate battery or AC supply.

20. Make a ground jumper from a length of 10-12 gauge stranded hookup wire, and connect one end to a solid ground point on your cart. Touch the other end to every connector shell, equipment housing, metal portion of the cart, etc.

21. It may help to make a sketch of your setup and look for unexpected current paths. Remember that any current flow will produce a voltage “drop” that, in fact, raises the voltage at the far end with respect to “ground,” and this voltage will look for any way possible to get there.

SAFETY CONSIDERATIONS: SAFETY FIRST, LAST, AND IN BETWEEN

If you connect AC power to your cart, there are several precautions you can take.

1. Only connect to 3-prong grounding-type outlets, and check them beforehand with a plug-in 3-lamp tester to make sure they are wired correctly and properly grounded. NOTE: These simple testers are quick and easy to use, and will unambiguously indicate the presence of a connection to the safety ground socket. What it cannot distinguish is whether the connection is properly to the ground wire or incorrectly to the neutral. While either will provide the necessary safety shunt in the event of a powerline short to a 3-wire “grounded” equipment housing, the wiring reversal can cause massive AC ground loop problems.

WARNING: 2-wire power cords have “polarized” plugs, with one blade (the neutral) slightly wider than the other (the hot phase). Modern receptacles, whether 2- or 3-prong, have one slot wider to match, but older 2-prong outlets have both slots narrow. Some individuals have been known to file, saw, or cut down polarized plugs so they will fit these older outlets, and either way in the newer ones. Applying the hot phase to the neutral side of any device is never a good idea, even if the housing is plastic and/or “double-insulated.”

ANOTHER WARNING: If you absolutely must use a 3-to-2 adapter, be sure the grounding lug or pigtail lead is connected to the screw between the two outlets, and then check with the tester, because in some locations the receptacle mounting box is not grounded. Be very afraid if this is the case—run a 3-wire extension cord to a known good (tested) outlet.

2. Use only 3-wire extension cords, and check them at the far end with the tester. WARNING: On a non-union show I was given an extension cord by the electric department. It had a 3-prong plug and receptacle, but failed the test. I opened the plug to see if the ground wire was disconnected, and found to my horror that the electricians had made all their “3-wire” extension cords with 2-wire cable because it was cheaper and lighter.

3. You can buy a plug-in G.F.I. (Ground Fault Interrupter, also G.F.C.I.), and this is particularly important if you are working outdoors or on a damp concrete floor. In addition to providing overcurrent protection like an ordinary circuit breaker, it senses any current differences between the current going out on the hot wire and returning on the neutral. If there is more than a 5 mA difference (such as current flowing through your body to ground instead of the neutral wire), the unit shuts off the power. 5 mA will give you a nasty shock, but (hopefully) not induce ventricular fibrillation in your heart. WARNING: G.F.I. receptacles haveTEST and RESET buttons. Test them every time before use. IMPORTANT: Some G.F.I. units will trip if there is an interruption in the AC power supplied to them, so they cannot be used on the camera truck for overnight battery charging if the truck will not be plugged in until it is driven somewhere or if the AC supply to the truck is disconnected when it is moved during the night. (NOTE: This is also true of some “automatic” battery chargers.)

4. You can buy an AC power 1:1 isolation transformer in various sizes, from 100 W to 1 KW or more. If you need to run on AC during the day, and are working in damp or exterior locations, this will isolate the power sent to your cart completely from ground, so in the event of a leakage problem, what would have been a fatal shock will be only a tingle. You can feel a tingle from less than one-thousandth of an amp (< 1 mA). WARNING: “Tingles” of any sort are a warning sign that must not be ignored. Locate the problem and fix it before you or someone else is electrocuted.

ANOTHER WARNING: Stepdown “transformers” used to lower foreign 220 V AC power to 110 V are often not true transformers with separate primary and secondary windings, but rather autotransformers with a single, center-tapped winding. While these units will halve the voltage, they do not provide any isolation, and the full 220 V may appear in the event of an internal short, including to the case. Many of them do not provide proper grounding through the third pin as well. With the unit disconnected from both AC power and 110 V equipment, use an ohmmeter to check for continuity between any of the output terminals and any of the input terminals. If there is none, you have a true transformer and not an autotransformer. Also check that there is continuity between the input and output ground terminals.

5. Always plug all your AC power cords into a single outlet (or both outlets of one duplex receptacle), unless the total current draw would overload the circuit. Most sound gear (except for things like playback amps) requires very little current, so using cube taps is acceptable. (I have extension cords that terminate in duplex outlet boxes, providing six heavy-duty 3-prong receptacles.) There are two reasons for this practice: 1, all the safety grounds will interconnect at just one point, avoiding power source ground loops from different ground potentials; and 2, in the U.S., consumer 110-V power is usually distributed as 3-wire 2-phase 220-volts. While the 2-phase wires are 110 volts with respect to the common neutral wire, there is twice that voltage between them. A typical building’s internal wiring has half the branch circuits supplied by one phase and half from the other. If you happen to power some of your gear from one branch and the rest of it from another branch fed by the opposite phase, their hot 110-V power conductors will have a 220-V difference. This increases: the chance of fireworks if there is an error in your cart’s internal AC power wiring; the potential severity of a shock from leakage between two pieces of equipment, particularly with those having 2-wire power cords; and amount of AC hum and buzz that can be induced in audio circuits.

6. When using AC outlets provided by the electric department, especially when supplied from a generator, there is another potential danger. The outlets boxes are connected with runs of 4-0 heavy cables that use color-coded pin connectors. In the event that there is a mis-wiring, 220 volts (or 208 V for 3-phase) can appear on the “110-V” outlets. Even if the cables are connected correctly, if the neutral wire becomes disconnected anywhere between the load and the generator, all the loads connected to one phase will be connected in series with all the loads connected to the other phase, with the result that the full voltage will be applied to the combination. Unless both total phase loads happen to be exactly equal (unlikely), the greater load group will get less than 110 volts and the smaller load group more than 110 volts. Sometimes a lot more.

If you use external batteries to power your equipment, there are different precautions to take.

1. WARNING: Batteries, even small ones like alkaline AA cells, can produce surprisingly large short-circuit currents. A shorted battery can get hot enough to melt plastic, and may rupture and spray corrosive chemicals all over. Short-circuit currents (often over 100 A) can heat wiring to incandescence and start fires. SLA (Sealed Lead- Acid) batteries are especially dangerous. If you don’t want your cart to disintegrate in a shower of sparks like things do in the movies (think Star Trek, where they never invented fuses or circuit breakers … or seat belts either), you need to fuse each battery directly at its terminals. Auto parts stores sell in-line fuse holders that are ideal for this purpose. A 20 Amp mini-blade fuse is a good choice for a small battery (30 Amp-Hours or less). If you use a larger battery, get a fuse that is rated for 2-3 times the maximum current draw of all your equipment.

2. WARNING: Unlike AC current, which passes through zero twice every cycle, DC current is much harder to interrupt. If you wire up your own cart (or have someone else do so), be sure to use fuses or circuit breakers specifically rated for DC. (Typical 5 Amp 3AG/AGC glass fuses are rated 110 VAC but only 32 VDC, so check your selections carefully.) Automotive fuses are all designed for at least 12 VDC. They should still function properly at 15 VDC or 18 VDC, but 48 VDC may be too much for them. Many years ago, when stages and theaters still had wall outlets with 110 V DC, a mixer (not me) mistakenly plugged his cart into one. The current continued to arc through all the blown AC fuses and melted down much of his equipment before the smoking power cord was yanked from the wall.

3. The “hot” center contact of many coaxial low-voltage DC power connectors is flush with the end of the plug, and can short out to grounded metal surfaces if the plug brushes against them. I have installed in-line fuse holders in each of these power cords, with readily accessible 5 A fuses (rated less than the 20 A main fuses so only that particular branch fuse will blow).

4. Many fuses have a “time” rating as well as a current one. Fast (usually marked “F”) fuses provide the maximum protection, but may blow unnecessarily with loads that draw a larger initial current. Motors and incandescent lamps are prime offenders. Delay or Slo- Blo (marked “T” for time-delay) fuses can carry current in access of their rating for a short time and should be used for these applications. Unfortunately, modern microelectronics can be damaged by current pulses too brief to be stopped by conventional fuses. Tiny Micro- and Pico-Fuses, which look somewhat like 1/8-watt resistors, are usually soldered directly to the circuit board because they are designed to limit the spread of damage rather than prevent it. If you happen to have a piece of equipment that uses these, and they do occasionally blow without any other damage, you can avoid unsoldering them and soldering in replacements by installing two single-lead sockets on the circuit board and then simply plugging in the fuse’s wire leads.

5. Another new fuse type is the “thermal fuse.” These fuses will open above their rated current like a regular fuse, but they will also open if their temperature exceeds a certain value. They are designed to protect components such as motors, which can get too hot if they are overloaded for long periods. Some thermal fuses are one-shot, and must be replaced if they blow. This is difficult because not only are they are soldered in, but they have to be located next to the motor’s windings where they can sense the temperature. Twelvevolt air compressors (used to inflate sound cart tires) are a good example. If you have to replace one of these fuses, you can get an equivalent unit that is self-resetting, and it will automatically restore the connection after it cools down.

CODA

In closing, let me warn you that the goat’s blood trick that works so well with radio mikes is useless for ground loop problems. You need blood from a cute little puppy or kitten.

Text and pictures ©2013 by James Tanenbaum. All rights reserved.